Guangdong, Guangzhou, 22 de noviembre de 2025 – Detrás de la inmensa potencia y el movimiento preciso de cada excavadora se encuentra una red de componentes críticos que trabajan en perfecta armonía. Entre los más vitales, aunque a menudo pasados por alto, se encuentran los sellos hidráulicos. Estos componentes especializados son los guardianes del sistema hidráulico, asegurando que la inmensa potencia que impulsa las plumas, los brazos y los cucharones de la máquina se contenga y controle de manera eficiente.

Los sistemas hidráulicos son el alma de una excavadora, y los sellos son esenciales para mantener la presión, prevenir fugas y mantener alejados los contaminantes. Una falla en un solo sello puede conducir a una reducción del rendimiento, costosos tiempos de inactividad y una importante contaminación ambiental.

Tipos comunes de sellos en una excavadora

Las excavadoras utilizan una variedad de sellos, cada uno diseñado para una función y ubicación específicas dentro del complejo circuito hidráulico. Los tipos principales incluyen:

1. Sellos de pistón

Ubicados en el pistón dentro del cilindro hidráulico, estos sellos son la barrera principal que separa los lados de alta y baja presión del cilindro. Son cruciales para convertir la presión del fluido hidráulico en la poderosa fuerza lineal que mueve el brazo de la excavadora. Están diseñados para soportar presiones extremas y evitar fugas internas.

2. Sellos de vástago / Sellos amortiguadores

Actuando como la primera línea de defensa, los sellos de vástago se colocan en la culata del cilindro. Su función principal es evitar que el fluido hidráulico se filtre fuera del cilindro cuando el vástago del pistón se retrae. También juegan un papel clave en el mantenimiento de una fina película de aceite en el vástago para lubricar el sello limpiador que lo acompaña. Los sellos amortiguadores se utilizan a menudo en tándem con los sellos de vástago en sistemas de alta presión para absorber los picos de presión y extender la vida útil del sello de vástago principal.

3. Sellos limpiadores / Sellos rascadores

Montados externamente en el cilindro, los sellos limpiadores tienen la tarea de mantener el entorno externo fuera. A medida que el vástago del pistón se mueve hacia adentro y hacia afuera, puede recoger suciedad, polvo, barro y otros contaminantes abrasivos. El sello limpiador raspa estas partículas del vástago antes de que puedan entrar en el cilindro y causar daños a los sellos del vástago y a todo el sistema hidráulico.

4. Anillos guía / Anillos de desgaste

Si bien no son un elemento de sellado en el sentido tradicional, los anillos guía son socios esenciales de los sellos. Instalados tanto en el pistón como en el vástago, evitan el contacto metal con metal entre el pistón y el orificio del cilindro, y el vástago y la glándula. Esto asegura un funcionamiento estable y suave, reduce la fricción y evita el desgaste que podría comprometer la efectividad de los sellos principales.

5. Juntas tóricas y juntas

Estos son los sellos estáticos más comunes que se encuentran en una excavadora. Utilizados en aplicaciones donde no hay movimiento relativo entre las piezas, como entre bloques de colector, conexiones de tuberías y placas de cubierta, las juntas tóricas y las juntas proporcionan un sellado confiable y sin fugas para contener el fluido y la presión.

La importancia de la calidad y el material

El exigente entorno dentro de una excavadora, caracterizado por la alta presión, las fluctuaciones de temperatura y la exposición a elementos agresivos, requiere sellos fabricados con materiales duraderos. Los materiales comunes incluyen caucho de nitrilo (NBR) para aplicaciones estándar de aceite mineral, poliuretano (PU) para una excelente resistencia al desgaste y a la extrusión, y fluorocarbono (FKM/Viton) para resistencia a altas temperaturas y a productos químicos.

Invertir en fiabilidad

"Elegir sellos de alta calidad y específicos para la aplicación no es un gasto; es una inversión en el tiempo de actividad y la longevidad de la máquina", dice un portavoz de Guangzhou Mido Oil Seal Firm. "Un sistema de sellado robusto es fundamental para la eficiencia, la fiabilidad y el cumplimiento ambiental de la maquinaria pesada como las excavadoras."

A medida que las excavadoras continúan evolucionando con mayor potencia y precisión, la tecnología detrás de sus soluciones de sellado avanza en paralelo, asegurando que estas maravillas de la ingeniería puedan abordar los trabajos más difíciles del mundo.

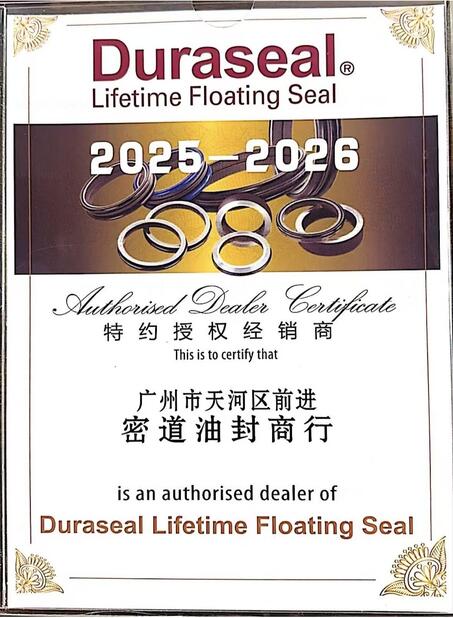

Acerca de Guangzhou Mido Oil Seal Firm

Guangzhou Mido Oil Seal Firm es un proveedor global líder de soluciones de sellado de alto rendimiento para las industrias de la construcción, la minería y la agricultura. Con un compromiso con la innovación y la calidad, proporcionamos los componentes críticos que mantienen la maquinaria del mundo en movimiento.

Contacto con los medios:

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!